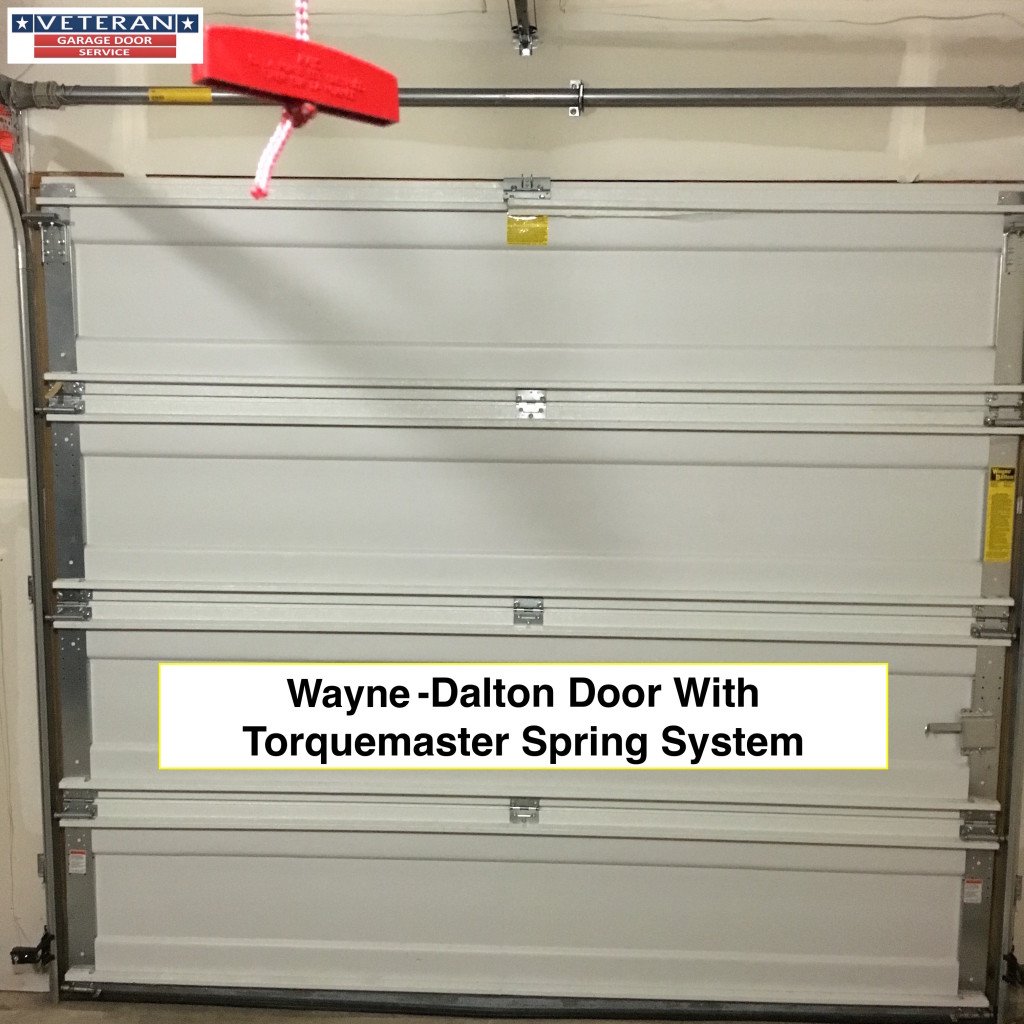

Wayne Dalton Torquemaster spring system is a system that was developed in an attempt to improve on

the torsion spring system. Torquemaster systems use a spring system that is enclosed inside a hollow

torque tube that mounts on the header above the garage door opening. It is similar to a standard

torsion spring system in that it uses cables and drums to do the lifting with the spring(s) providing the

force to balance the weight of the garage door.

Torquemaster systems are sold exclusively by Wayne Dalton and several changes have occurred over

the past few years to the Torquemaster system in an attempt to improve its function. The

Torquemaster system utilize smaller springs that are inside the torque tube rather than the larger higher

rated springs in standard torsion springs. It is very difficult to tell if a Wayne Dalton Torquemaster spring

has broken because the spring is not visible. The only way to diagnose this is if the door is difficult to

open. In standard torsion spring systems you can visibly see that the spring is broken.

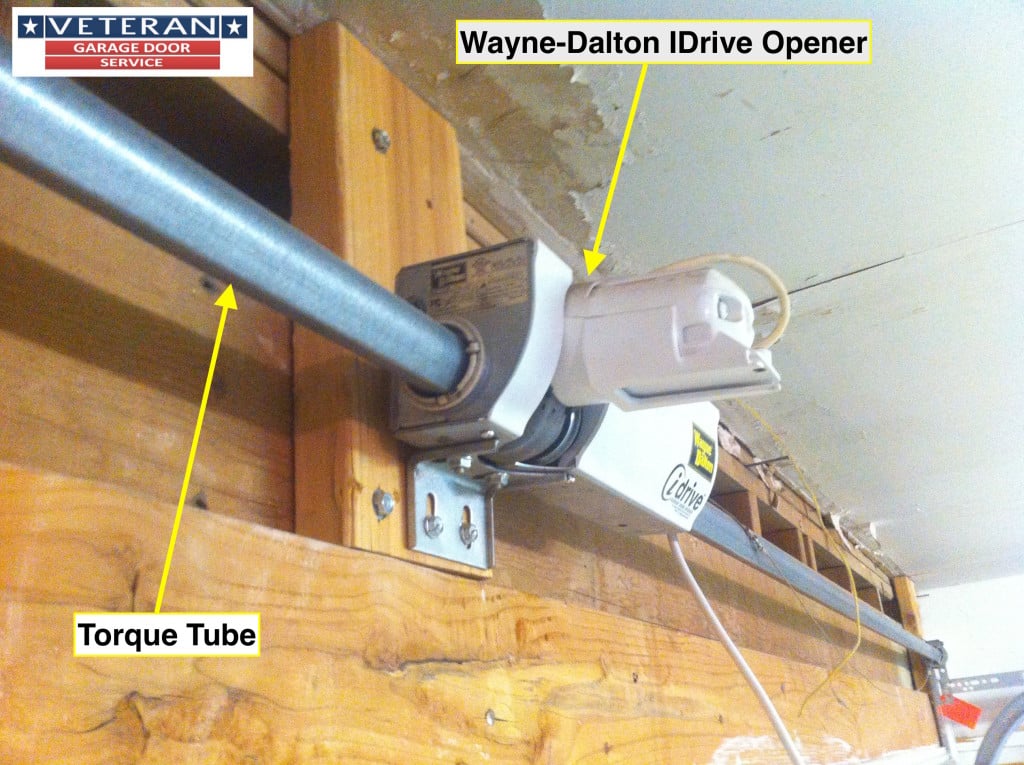

The Wayne Dalton Torquemaster system utilizes parts similar to a standard torsion spring system, but

also use more moving parts that can fail. First there is a torque tube that holds the spring(s) inside it

along with a plastic spacer tube to prevent the spring(s) from rattling as the garage door opens and

closes. There can be one or two springs in this system, but the only way to know is to look for the

adjustment cone and gear at each end. In one spring systems the adjustment cone will be only on the

right side and in two spring systems there will be an adjustment cone and gear on each end.

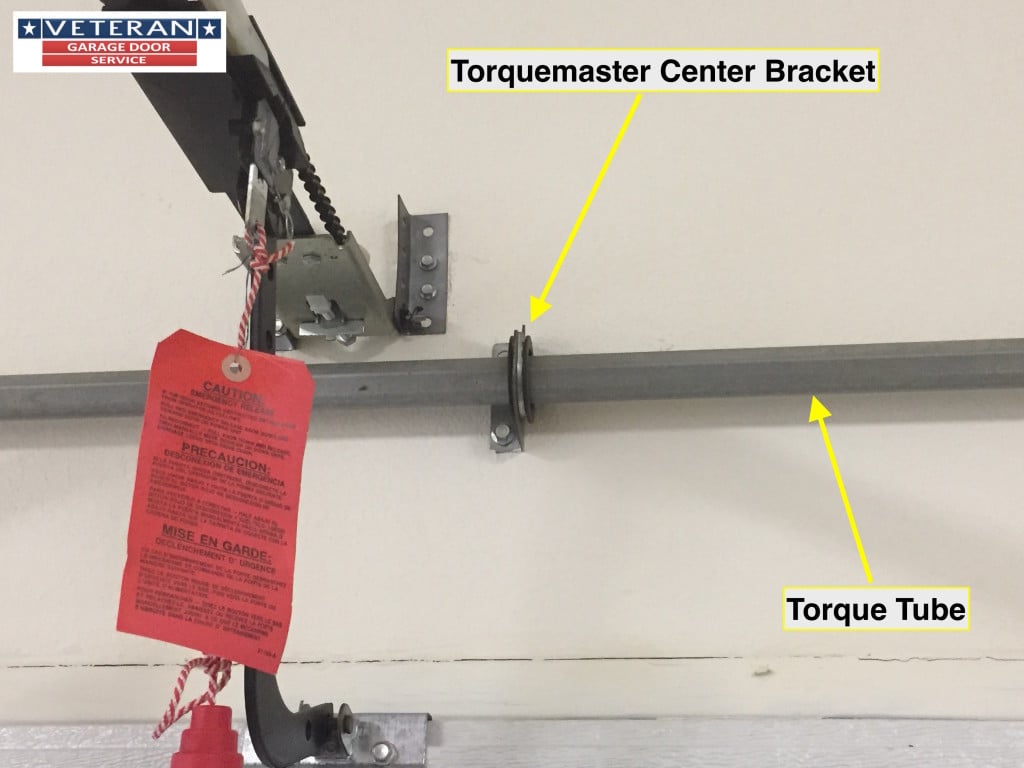

These gears, whether made of metal or plastic, are another point of failure not present on standard torsion

spring systems. Torquemaster utilizes a center support bracket, but it is only to support the weight of

the torque tube. The end plates are also different. Torquemaster end brackets are designed to hold the

adjustment cone and gears. Then there are the drums and cables. The drums are made of plastic and are

only about 2 inches in diameter as opposed to the 4 inches or larger for standard torsion spring systems.

The smaller drums require longer cables. The smaller drums also require winding the springs more,

which causes the spring(s) to fail sooner.

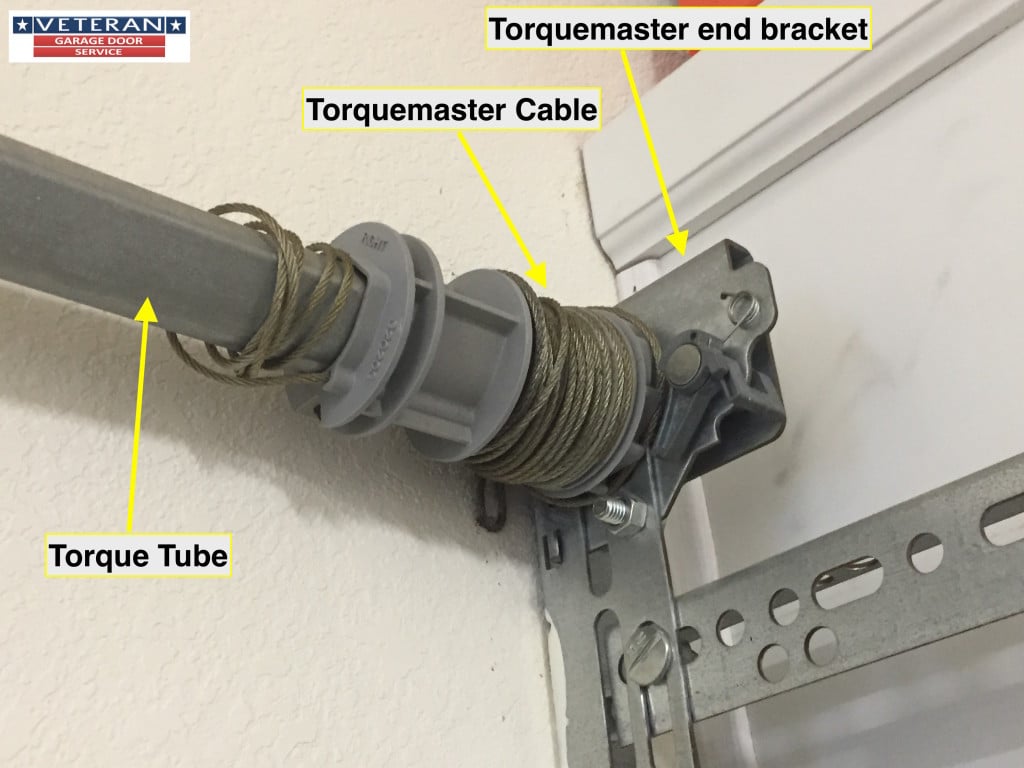

Wayne Dalton Torquemaster spring systems as we have already discussed uses springs that are hidden

inside the torque tube. This, at first, seems like a reasonable idea as if the spring is inside the torque

tube it will be protected from dirt and rust that cause premature failure. The problem is that the springs

are made with a much smaller gauge wire that has to be wound more. This additional winding leads to a

shorter life for the springs. Another problem with the Torquemaster design is that it uses a gear box at

the ends. These gear boxes whether made of plastic or metal are subject to breakage and failure. The

Torquemaster system also utilizes smaller drums which in turn calls for more winds of the spring. The

more you wind a spring the shorter the life span of the spring. These factors lead me to the opinion that

the Wayne Dalton Torquemaster system is far inferior to a standard torsion spring system.

If you have a Wayne Dalton Torquemaster system and the spring(s) have failed, it is possible to replace

the springs, although we recommend converting to a standard torsion spring system.

If you choose to repair the Torquemaster system it will require quite a bit of time and labor. First you

must release any tension on the spring(s). To do this you will have to loosen the retainer bolts at the

ends by the adjustment cones and gears. Depending on what model system you have you will use a drill

with a socket adapter or wrench to unwind the tension on the spring(s). The adjustment cone has

numbers from 0-20. When the spring is completely unwound it should have the zero lined up with the

hash mark. Once the spring is unwound you will have to disassemble the winding cone and gears. It is

important to inspect the gears for damage and replace if necessary. Start on the right side of the garage

door and then proceed to the left side. There will only be an adjustment cone and gears on the left side

if the system has two springs. Once the left side is disassembled , the center support bracket tab must

be bent to allow the torque tube to be removed. Next you will have to remove the torque tube and

place it on the ground. Next you will need to remove the spring from the right side and then from the

left side if two springs are present. Removing the springs can be difficult as the plastic spacer must also

be removed from the tube along with the spring(s). Once the old springs are removed you will need to

install the new springs and plastic spacers into the torque tube. When installing the new springs it is

normal for a small portion of the spring as well as the shaft to extend out past the end of the torque

tube. You will need to use vice grips to hold the springs in place while you raise the torque tube and

reinstall the adjustment cones and gears. Start reinstallation on the right side and then proceed to the

left side. Once you have reinstalled the adjustment cones and gears you will need to rewind the

spring(s) using either an electric drill or wrench depending on the system you have. Start with the right

side and then proceed to the left side. The number of winds required is dependent on the height of the

garage door. Before you begin you will need to get accurate measurements of size and weight of the

garage door so that proper replacement springs are ordered. You will also have to order appropriate

replacement gears and adjustment cones if needed for your Wayne Dalton Torquemaster system.

As I stated earlier we recommend converting Wayne Dalton Torquemaster systems to standard torsion

spring systems. The standard torsion spring system parts are more reliable and more readily available. I

also like being able to visually inspect the spring(s) and to perform periodic oiling of the standard torsion

springs. Keeping the torsion springs lubricated helps prolong the life of the spring(s) and helps reduce

stress on other components of the garage door system.

Rate this parts