Veteran Garage Door Online Garage Door Spring Repair Promotions in the Dallas – Fort Worth Metro and Houston Metro.

| Garage Door Weight | Spring Gauge | Price (Installed) | Warranty |

| 60 Pounds | .207 | $259 | 1 Year Parts & Labor |

| 80 Pounds | .207 | $259 | 1 Year Parts & Labor |

| 90 Pounds | .207 | $259 | 1 Year Parts & Labor |

| 120 Pounds | .234 | $259 | 1 Year Parts & Labor |

| 140 Pounds | .243 | $259 | 1 Year Parts & Labor |

| 165 Pounds | .243 | $259 | 1 Year Parts & Labor |

Broken garage door spring(s) are one of the most common service call we receive. If you have a broken garage door spring you may not be able to open the garage door at all. Other symptoms of a broken spring can be the opener will open the door a few inches and then the door closes again, you may see the cables hanging loose from one or both sides of the garage door and the most obvious is you look up at the springs and see the broken spring. Every spring job we go out on we physically weigh the garage door. This is the single most important step to determine the proper size spring for your garage door. It is also important to know the height of the garage door. We use the weight of the garage door to figure IPPT (Inch per Pound Turn), the IPPT is then used to determine the proper size spring(s) to use for your garage door. It is very difficult to give accurate estimates over the phone for spring replacement jobs without knowing the exact weight and height off the garage door.

When one of our certified technicians arrives at your home he will weight the garage door and note the height of the door. With this information he will Figure the IPPT and give you spring options for your garage door. These options will include the length of warranty for the particular spring(s) based on the rated life cycle of the spring(s) and the cost of the job including tax and labor.

Once you have made your decision on the spring(s) you want installed based on the information the technician provides you, the technician will complete the work according to industry guidelines. When the technician has completed the spring(s) installation he will then perform a balance check on the garage door to insure the door is functioning properly.

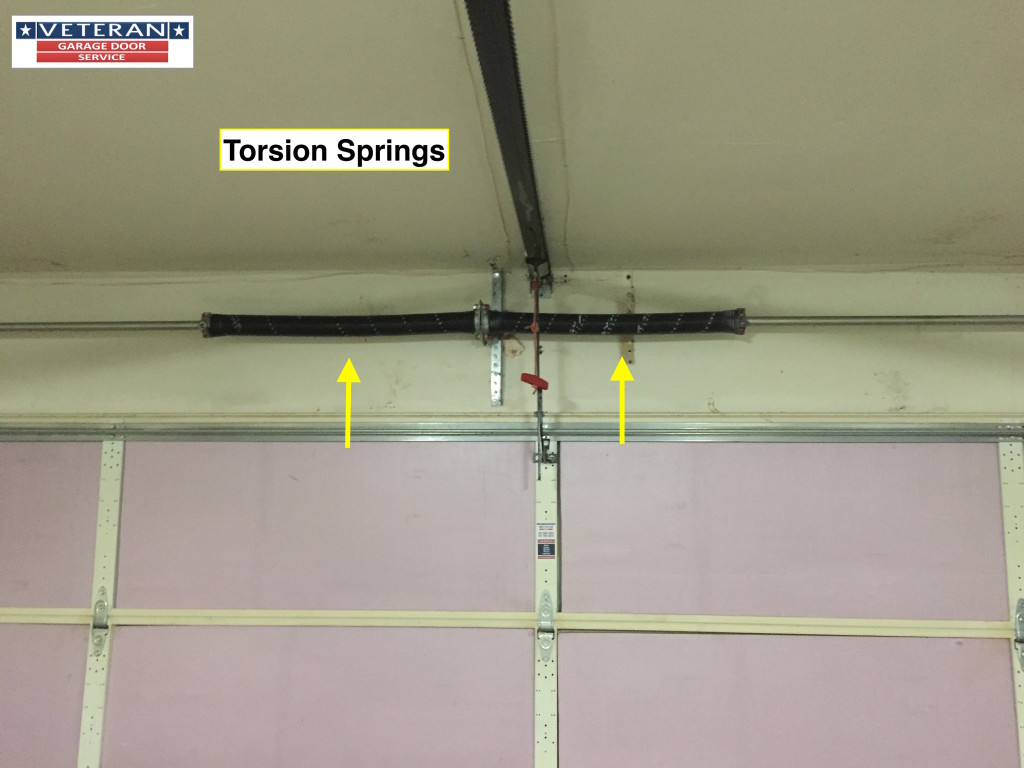

We only install torsion spring systems as they are much safer and more reliable than the older extension spring systems. We also recommend converting Torquemaster/Wayne Dalton systems to standard torsion springs because they last longer and are easier to maintain. If your garage door has Extension springs or a Torquemaster/ Wayne Dalton system we offer a conversion that includes all the necessary parts including the spring(s) and labor to convert your system. These parts include new drums, cables, spring bar, end bearing plates, center bracket and bearing and the spring(s).

Spring Conversions (Extension/Torquemaster/EZ-SET)

| Door Type & Size | Cost (Installed) | Warranty |

| 8×7 Classic Garage Door | $545 | 2 year parts 1 year labor |

| 16×7 Classic Garage Door | $645 | 2 year parts 1 year labor |

The last step is the maintenance and tune up of the door and opener along with a written safety inspection and warranty. This is a service we provide all of our customers when any other service is performed. We will lubricate all components in the garage door and opener systems that require lubrication. We will also check and adjust the opener travel and force limits as needed. The customer is then provide a written garage door and opener inspection form and a written warranty for all work performed.

Garage Door Extension Springs

The mounting for garage door extension springs is usually a simple process. They are usually located along the garage door sides or placed above the horizontal tracks. This particular style of springs stretch and contract during the door’s operation. They also are used for the door’s counterbalance of weight. Looking at residual garage doors, the majority have only two extension springs. One spring is set on each side of the door. Commercial garage doors, plus some of the larger residential garage doors, have more than one spring placed on each side of the door. Open loops, closed loops or clipped ends are used to ensure that extension springs are secured to the garage door pulley, frame, pivot pin, track hang or tension adjusting bolt.

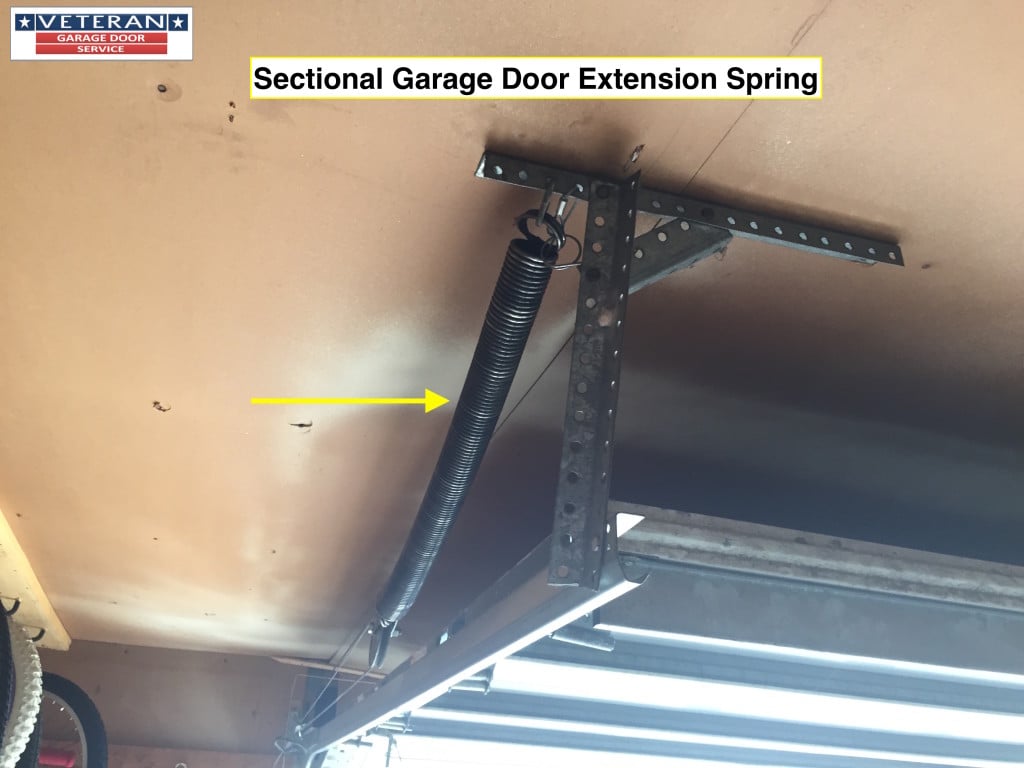

Sectional Garage Door Extension Springs

The most common kind of garage door extension springs in the United States is sectional garage door extension springs. This particular spring design stretches above and parallel to the sides on the horizontal tracking. These springs counterbalance the garage door by pulling on the door’s cables. As the door starts closing, the weight transfers to the cables from the tracks. During the process, the door gets heavier, which leads the springs to stretching and pulling against the cables so the door is balanced and it becomes easier to operate. Most often utilizing two springs, residential garage doors have a spring on each side of the garage door. Looking at the spring, one end attaches to an open-eye bolt. The open-eye bolt then connects to the angle iron, which holds to the track or to the beam in the garage frame. The other end of the extension spring has a pulley attached thanks to the help of a pulley fork. One cable end goes above the pulley and attaches to a cable adjustment clip. The clip has an S-hook attached to it in addition to a horizontal track. The other cable end rolls across a second pulley then reaches down to the bottom fixture which is on the lower section of the garage door. Both commercial and industrial overhead garage doors have an extension spring setup that resembles residential garage door setups. Heavier doors may have a special kit that is used to connect extensions springs ends. With this kit, two or more extension springs can be stretched simultaneously along each garage door side. While many commercial and industrial garage doors do have this specific design setup, there are some that have a single garage door extension spring on each side. Even with the alternative design the system pretty much functions the same as residential doors. Pulleys supply the needed lift in both designs, but pulleys used in commercial doors have the tendency to be stronger and have heavier weight capabilities to assist in the prevention of premature breakage.

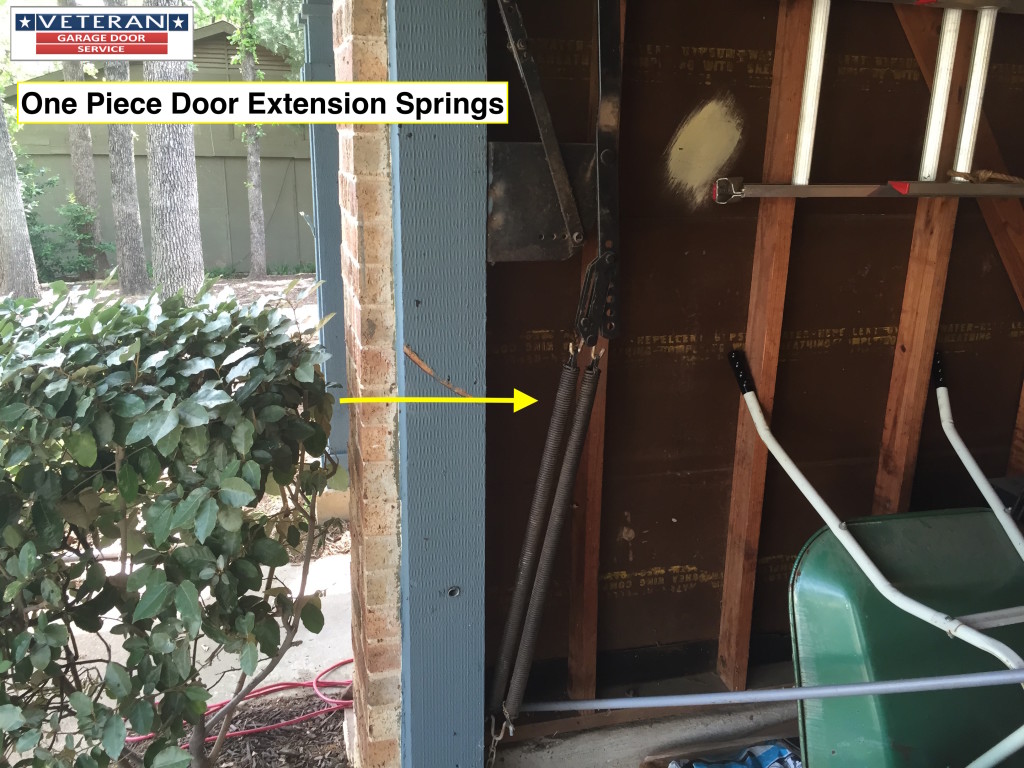

One- Piece Garage Door Extension Springs

The name perfectly describes it – one-piece garage door. Operating as one large unit, when the door opens the top of the door moves inside the garage. This door usually is lifted up by tracks, which forces the bottom of the door out of the garage. The extension springs then pull against the connecting point or pivot pin, which counterbalances the door’s weight. Because the door’s bottom moves in two directions, toward the outside of the garage as well as the inside of the garage, it cannot be weather stripped. Climates that don’t have harsh winters are where this particular kind of door is much more suitable. Extension springs that can counterbalance the door are used by one-piece garage door systems.

One-piece garage doors use one or two extension springs on each side, which makes for a total of either two or four springs on the door. The spring bottom is secured to an adjusting bolt that is hooked to a door jamb bracket. The spring top has a loop or clip that will be placed over a bolt or large pivot pin. The springs reach upward, being placed perpendicular to the garage floor. On the other end of the spring, you will find it is attached to a lever arm. That lever arm is attached to the garage door. In turn, the extension spring shortens and loses some of its stretch to enable the door to work.

Torsion Spring Hardware for Garage Doors

There are multiple pieces of garage door torsion spring hardware. Some of those pieces include anchor brackets, stationary and winding cones, spring blocking and cable assemblies. A garage door has many integral parts, including spring anchor brackets, cones and cables, while commercial and industrial environments usually see spring blocking in use. The stationary cone of torsion spring is connected to the garage door header by the spring anchor bracket. So the spring’s tension doesn’t force the bracket to spin loose, the bracket must be secured very tightly to the header. Spring anchor bracket sizing is determined by doing a measurement of the distance from the center of the shaft to the garage header or to the center line. Larger end bearing plates are required for larger cable drums. Because of their size, they need to be used with larger spring anchor brackets. Some anchor brackets are slotted, so bearings can be replaced easier and more efficiently. Those that are not slotted can be used as idler brackets in addition to spring anchor brackets. Idler brackets help in suporting the shaft because of the extra weight on a garage door.

Torsion Spring Cones

All torsion springs require a stationary cone, which keeps that end of the cone from moving. A winding cone is used on the other end of the torsion spring, which is secured to the shaft of the door. This particular design of cone applies tension to the door’s shaft which in turn provides lift to the garage door. These cones are primarily based on the spring’s interior diameter. As an example, a two-inch set of torsion spring cones can’t be used with springs that measure one-and-three-fourths inches or two-and-one-forth inches. The wind is another important characteristic of torsion spring cones. Left-wind cones have to be used on left-wind springs while right-wind cones must be used on right-wind springs. Come cones have dual wind capabilities, which means they have the ability to be used with the either left-wind or right-wind torsion springs that have inside diameter of corresponding size.

Cable Assemblies

Cables allow the shaft tension to lift the garage door. Pre-assembled cables for seven-foot and eight-foot-tall torsion spring garage doors.

Spring Blocking

As expected, torsion springs that are used for industrial and heavier commercial doors have larger inside diameters. To prevent the spring from sagging and resting on the shaft, the springs often have blocking located inside them. In these instances, the blocking slides over the shaft and fits down inside the spring between the stationary and winding cones. Whether wooden spring blocking or PVC spring blocking is used is dependent upon the spring size.