Garage door systems are made up of many moving parts that need periodic maintenance and

lubrication. Garage door openers also require periodic maintenance, adjustment and

lubrication. Periodic maintenance will insure that your garage door system provides many years

of quality service. Lack of maintenance and lubrication will lead to premature failure of parts in

the garage door system.

If your garage door is making lots of noise during use you need to perform a visual inspection of

all of the components in your garage door system.

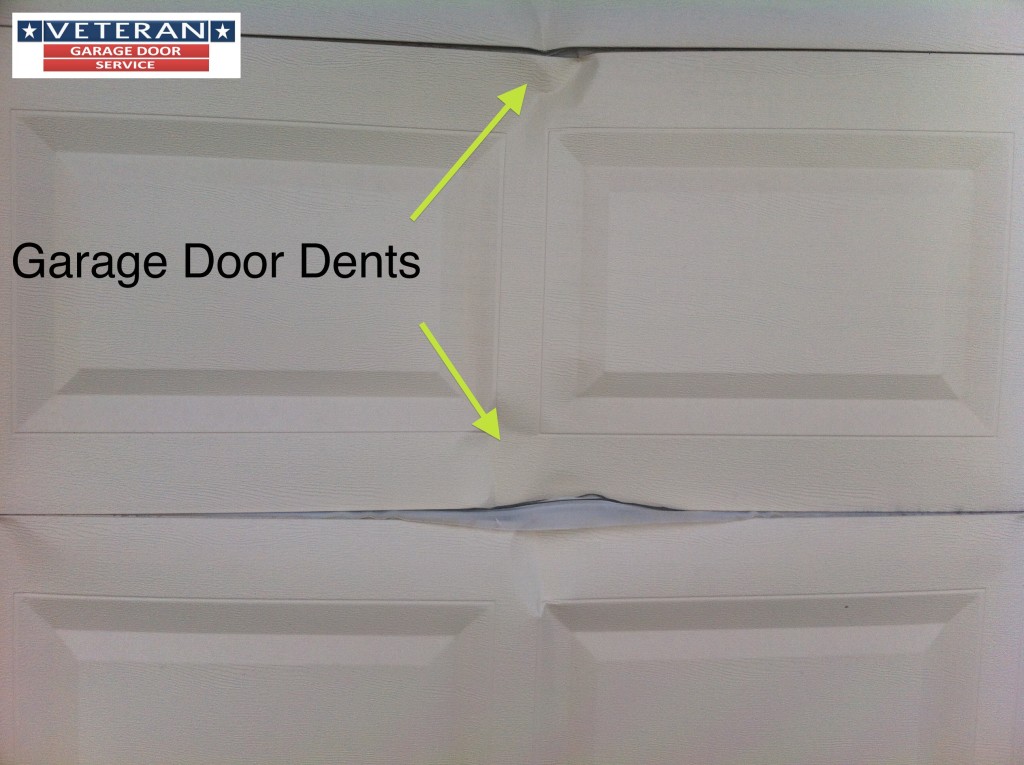

Start with a visual inspection of the sections/panels, looking for any signs of dents, bending,

creases or cracks in each panel.

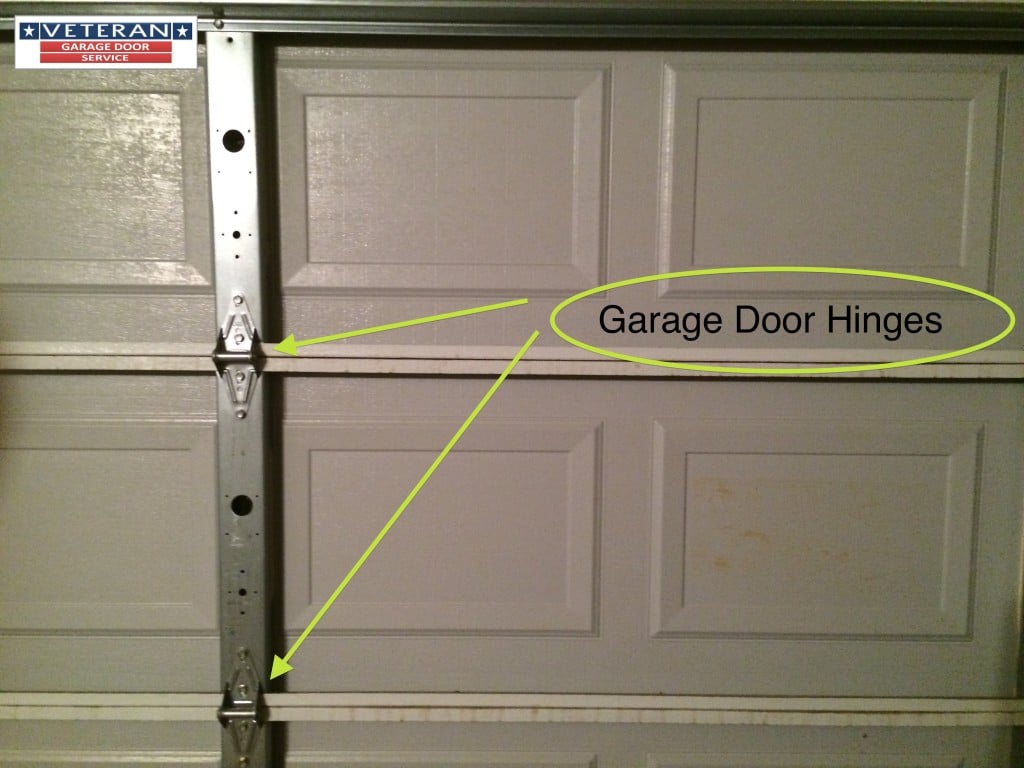

Then visually inspect each hinge. The hinges are the parts that

hold each panel together and allow the panels to separate and rejoin together as the door

opens and closes.

The hinges also carry the rollers that run in the horizontal and vertical tracks.

Inspect each hinge looking for any bending, twisting or breakage. If damage is discovered to the

hinges the damaged hinge or hinges should be replaced.

Hinges are not universal, hinges are

numbered, these numbers indicate the location on the door where the hinge goes.

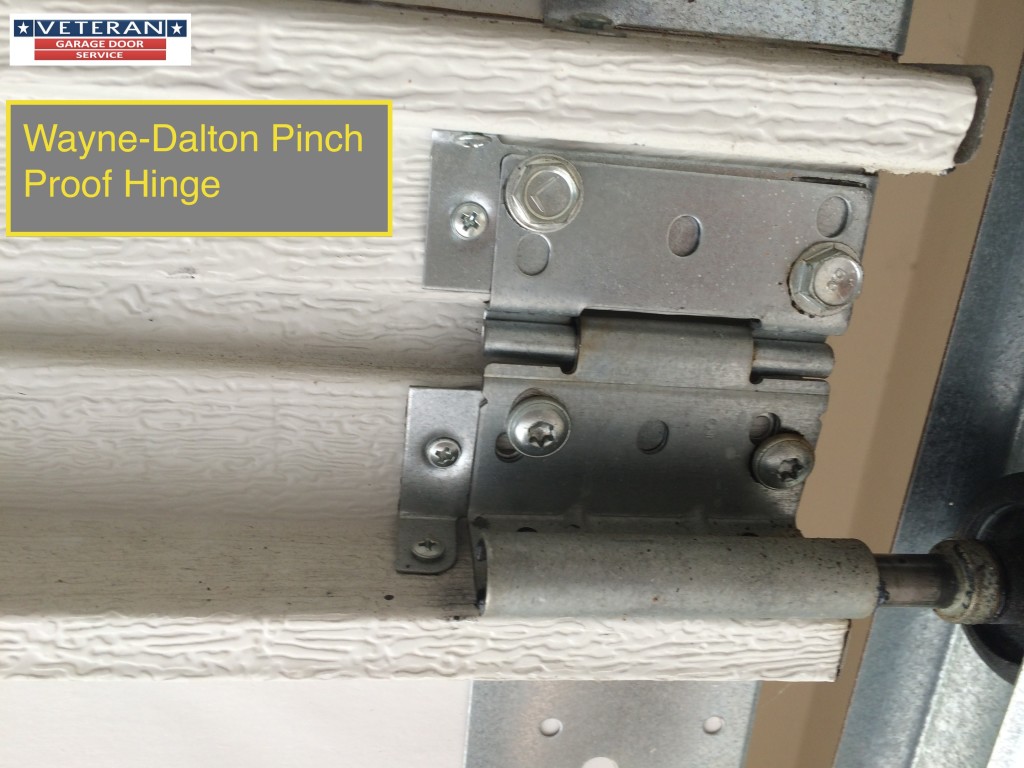

Some manufacturers like Clopay pinch less and Wayne Dalton use their own special hinges. Hinges

also come in a variety of gauges depending on the weight of the door. If you are attempting to

replace the hinges yourself, make sure you use the proper replacement hinge, remember each

hinge on your door is numbered, replace only with the same numbered hinge.

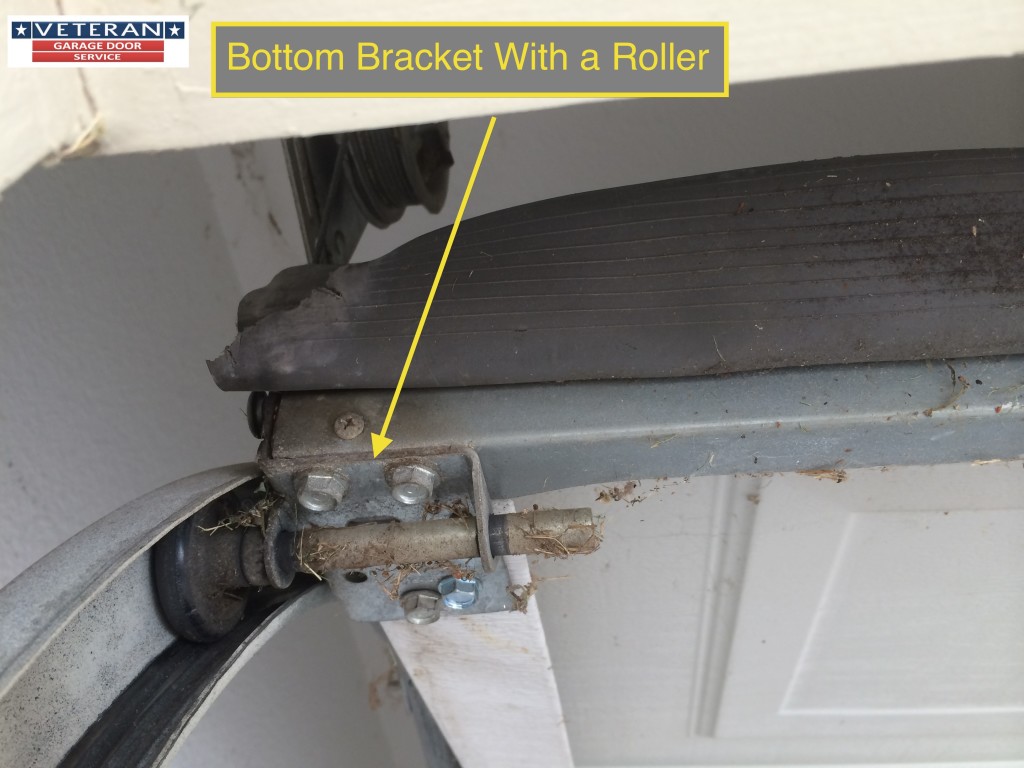

* Note: Never remove the bottom hinge on the outside edges that carry the rollers. These are

also the bottom brackets that your cables attach to. If you remove these brackets the cables

will fly loose and can cause serious damage even death as the cable are under great pressure

as they work with the spring system to actually lift the garage door.

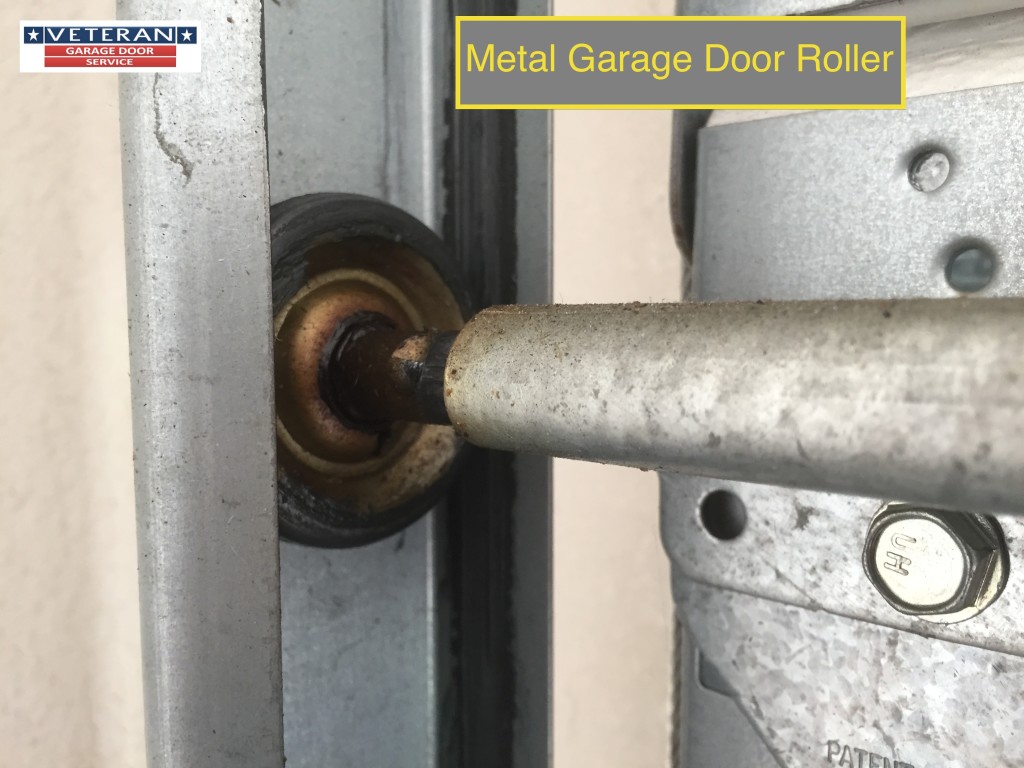

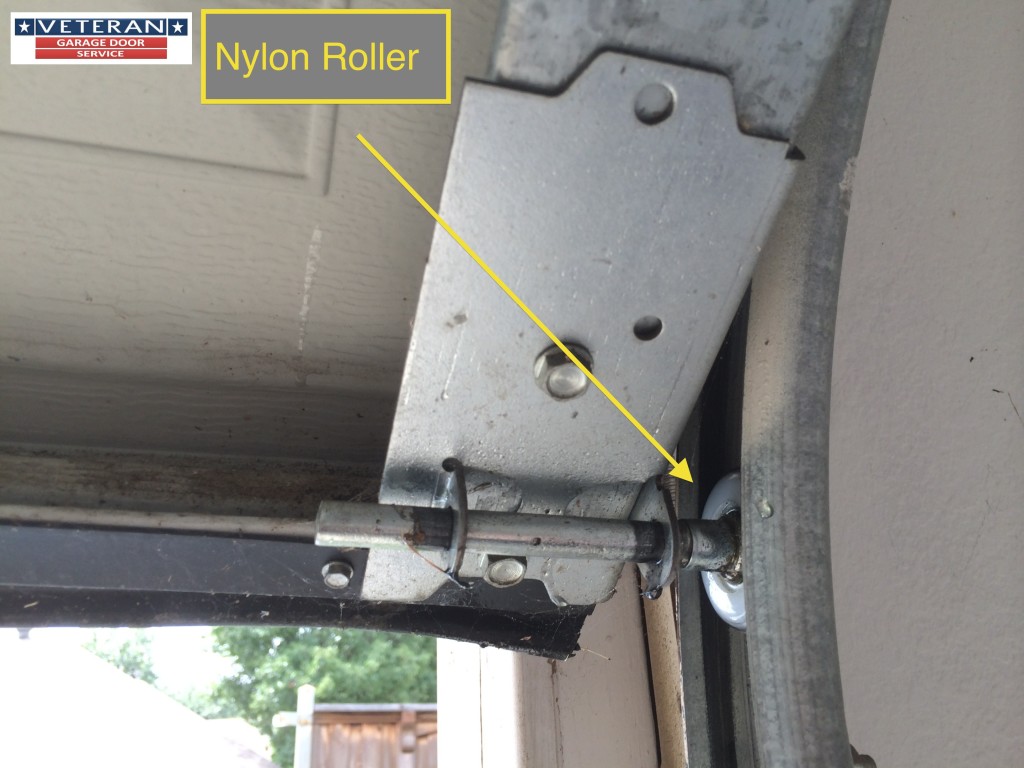

Next you will need to inspect each roller. The rollers run in the horizontal and vertical tracks.

The rollers could be made of metal with or without ball bearings, plastic without ball bearings

and nylon with ball bearings. You will want to inspect each roller making sure none are broken

and that there is not excessive play where the roller attaches to the steel shaft.

If damage is found, the roller or rollers should be replaced. There are several techniques to replace the

rollers, but it is best to have a garage door technician replace them.

*Note: Use caution when replacing the rollers as the garage door is heavy and if proper tools

and techniques are not used the door can fall causing serious damage and even death. It is

also important to note that the bottom rollers on each side are attached to the bottom

brackets. The cables also attach to the bottom brackets and are under great pressure and can

fly loose causing serious damage and even death.

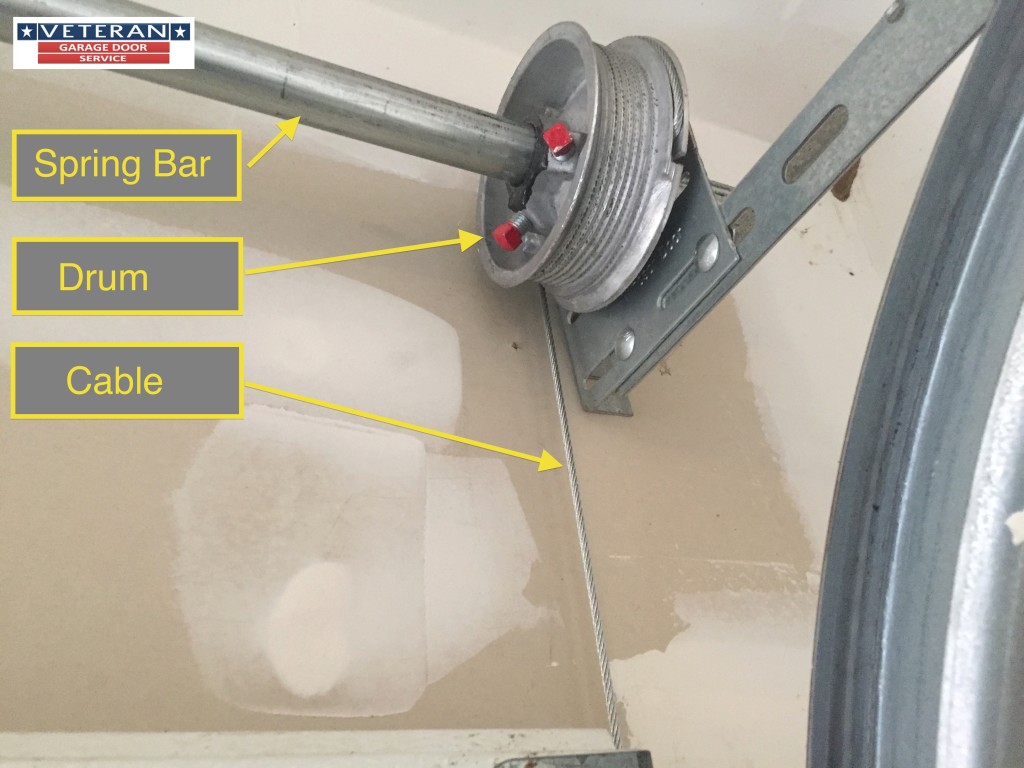

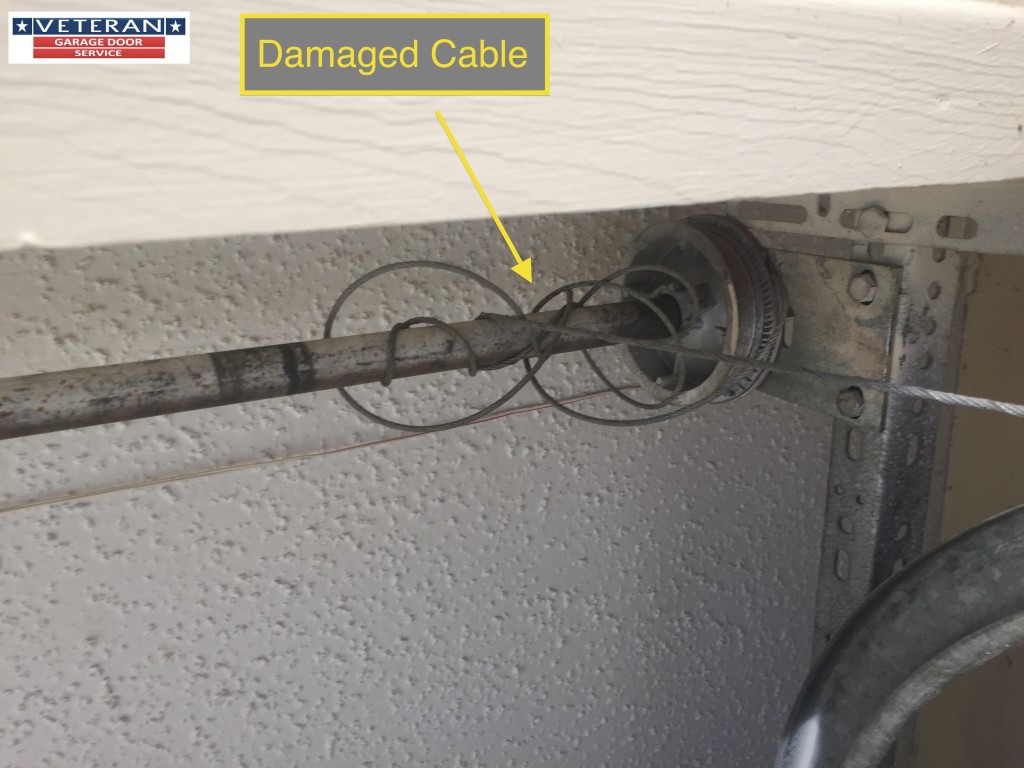

Next you will need to inspect the cables and drums. The drums are attached to the ends of the

spring bar/torsion tube that runs across the top of the garage door opening and carry the

springs, in an extension spring system. The cables attach the bottom brackets that are attached

to the bottom of the bottom garage door section. The cables then run up the height of the

garage door and attach to the drums. The cables actually lift the garage door and wrap around

the drums as the door opens and unwind from the drums as the doors closes.

You will want to check the cables for and fraying or kinks and the drums for cracks or signs of wear. If you find

damage to the cables or drums, call a garage door technician to perform these repairs.

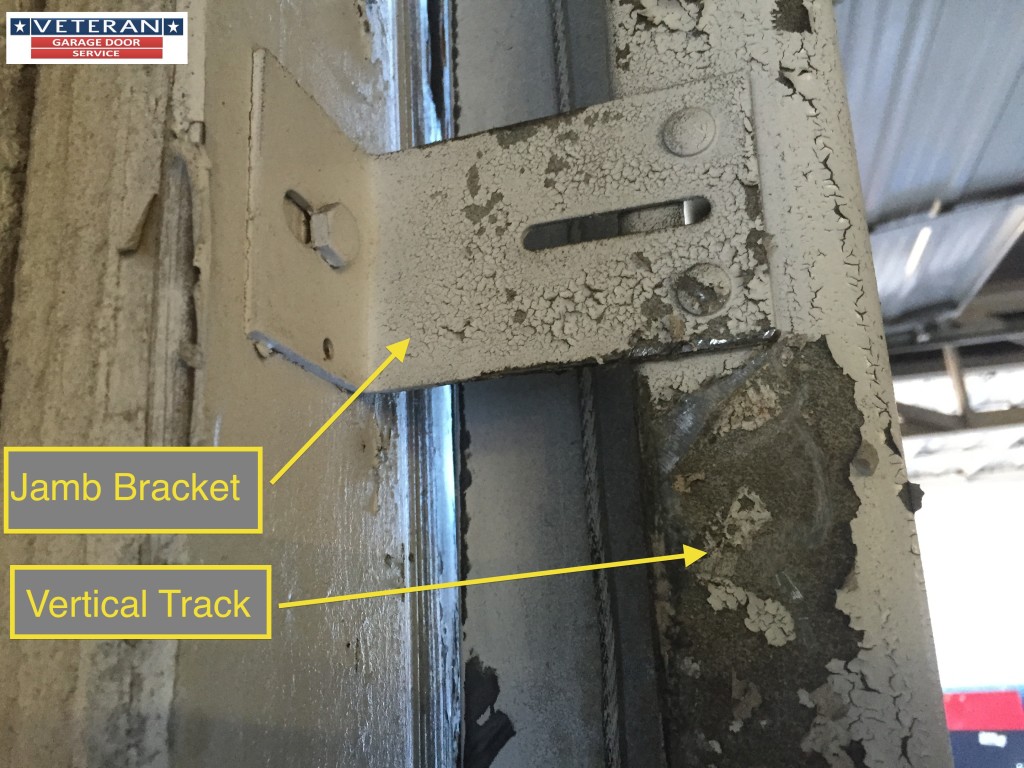

Finally you want to visually inspect the horizontal and vertical garage door tracks, looking for

any significant damage like bent or twisted tracks. You will also need to check and make sure all

bolts are tight. You will also want to check your jamb brackets. The jamb brackets attach the

vertical tracks to the vertical frame for the garage door opening. Make sure the jamb brackets

are secured tightly to the tracks and frame and not bent or twisted.

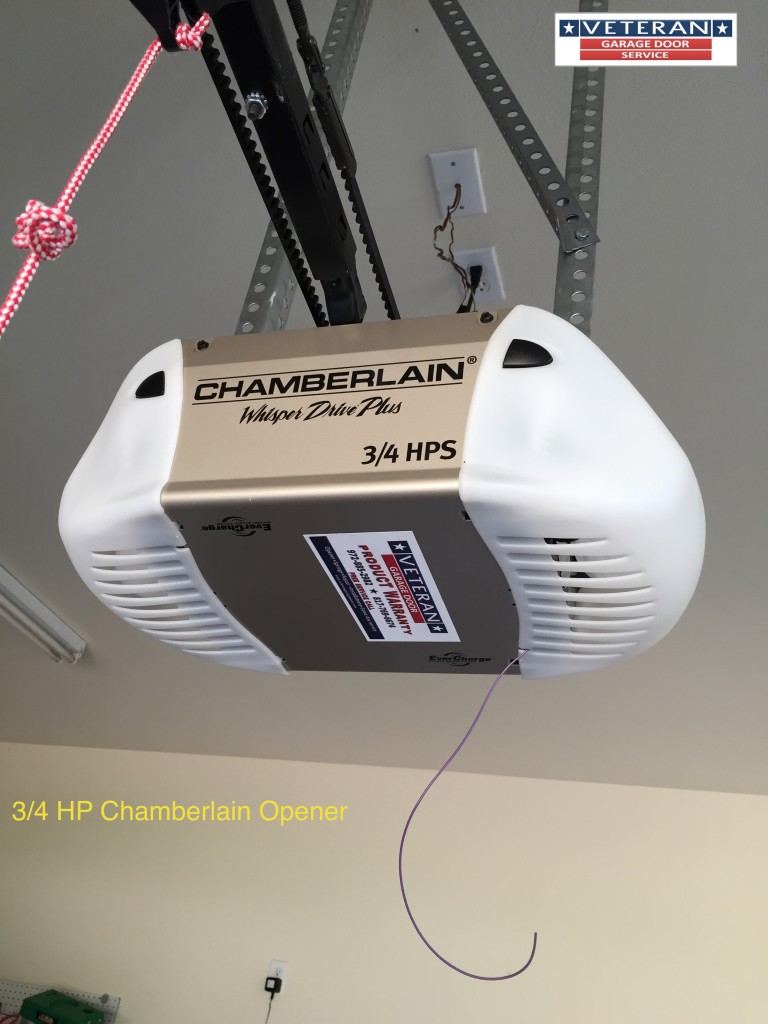

Inspecting Garage Door Opener

The garage door opener is the electric motor that opens the garage door for you. The garage

door opener needs periodic maintenance to keep it working properly. Garage door openers can

use a screw drive system, chain drive system or belt drive system.

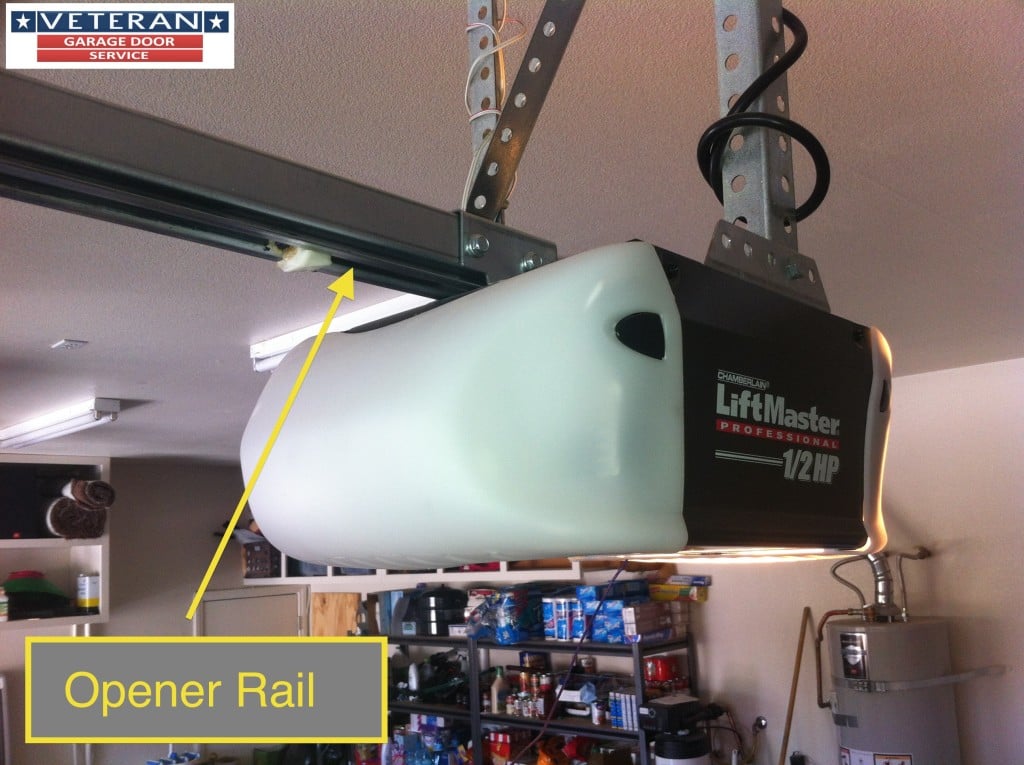

First do a visual inspection of the rail. The rail attaches above the spring bar to the header at

the top of the garage door opening. The other end of the rail attaches to the top of the garage

door opener motor. The rail should be inspected for any bends or signs of damage.

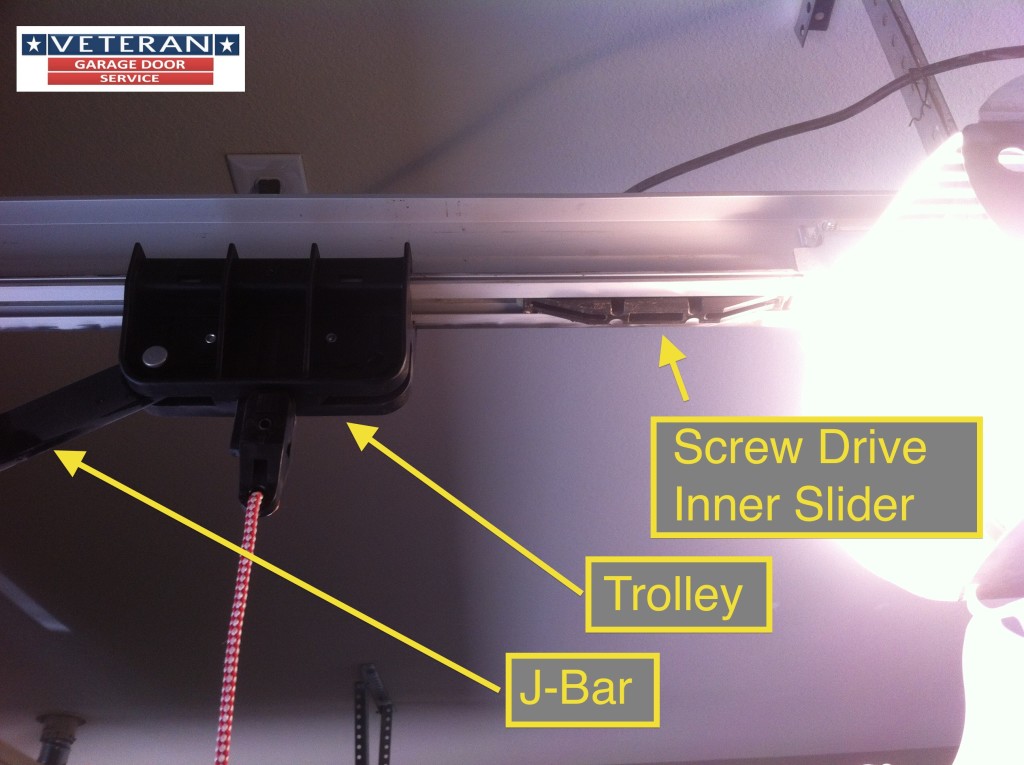

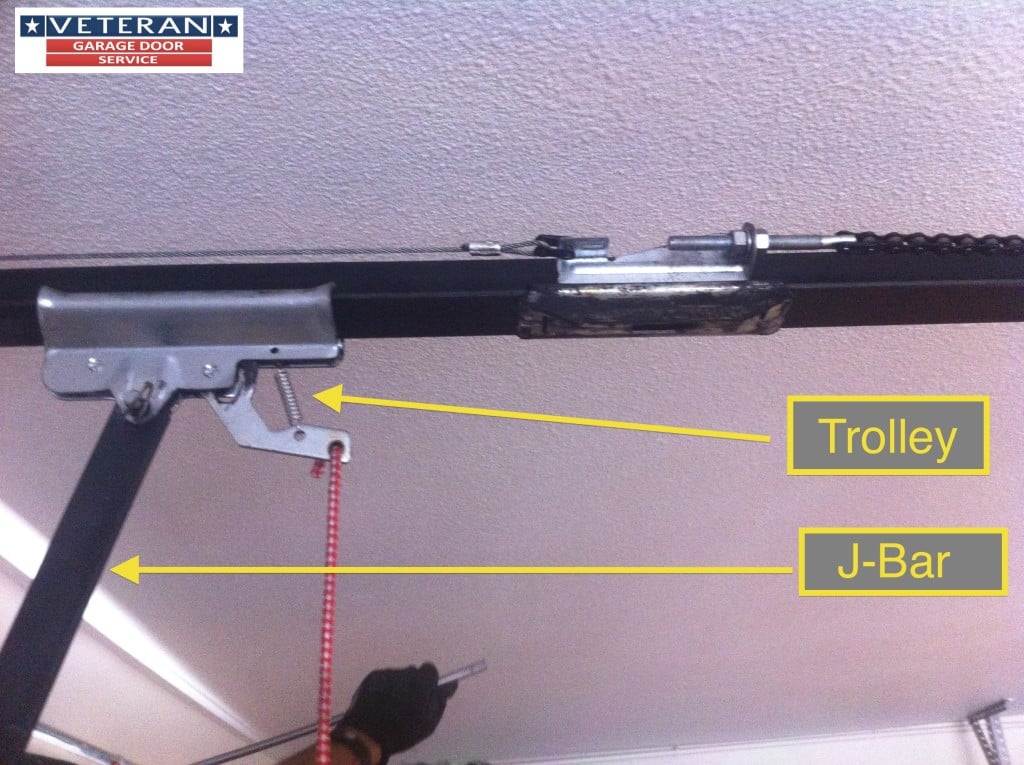

In chain and belt drive systems a trolley will be attached to the rail. The trolley attaches to the belt or chain

and to the “J” bar that attaches to the garage door. Inspect the trolley for any signs of wear or

damage. If damage or wear is found, have a garage door technician make repairs. In a screw

drive system, the screw runs in the center of the rail with a trolley that attaches to the screw

and to the “J” bar that attaches to the garage door. Inspect the screw for signs of damage or

wear. If damage or wear is found, have a garage door technician make repairs.

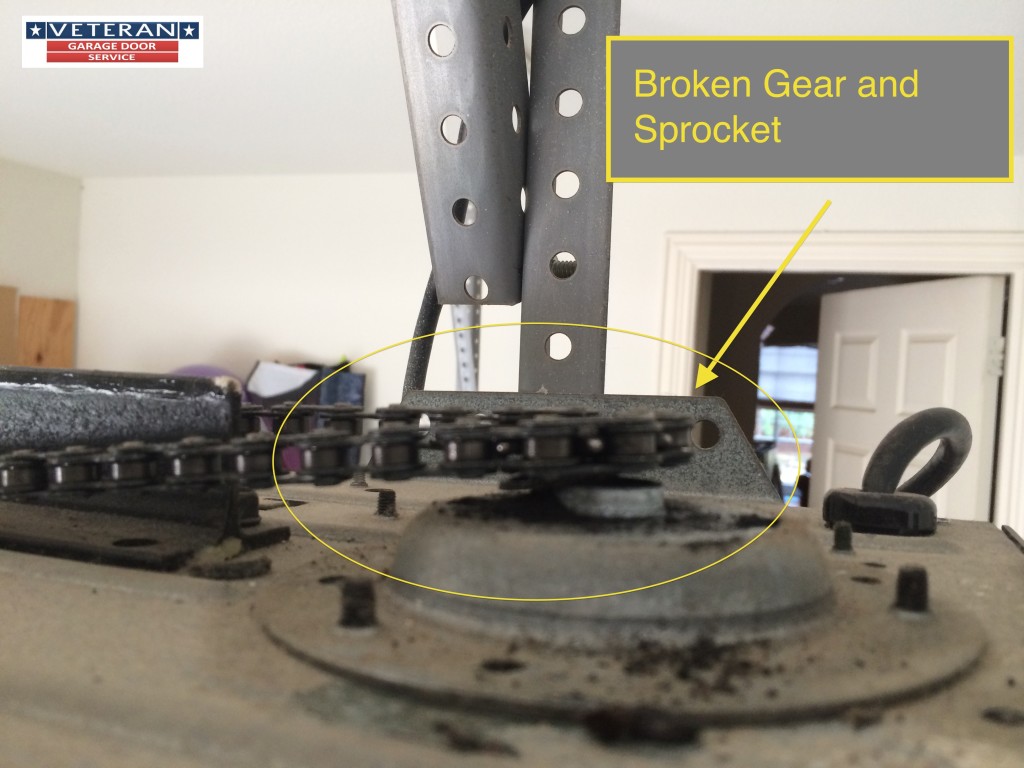

Next in a belt drive system or chain drive system you will want to visually inspect the gear and

sprocket. The gear and sprocket will be found on top of the garage door opener motor. You will

need to use a step ladder to inspect the gear and sprocket. *Note: Always use caution when

using a ladder to prevent accidental falls. The gear and sprocket will usually have a dust cover

clipped over it, remove the dust cover and inspect the gear and sprocket looking for metal

shavings and to make sure the gear and sprocket is straight and not leaning forward. If you see

metal shavings or the gear and sprocket is leaning forward or sideways, call a garage door

technician for repairs or to replace the opener.

In a chain drive system you will also visually inspect the tension on the chain. If the chain is too

loose and sags, you will want to tighten the chain using the adjustment bolt on the trolley.

The inspection is now complete and any needed repairs have been made, it’s time to lubricate

the garage door system.

First make sure you have a quality garage door lubricant, not a product like WD40. You can

purchase garage door spray lubricant at home improvement stores like Home Depot or Lowes

or from a garage door company.

Start with the rollers, spray each roller with lubricant making sure the ball bearings get

lubricated, if no ball bearings are present make sure the lubricant penetrates the point where

the wheel attaches to the steel roller shaft.

Next lubricate each hinge with the spray lubricant.

Next spray the torsion spring(s) with the lubricant.

Next spray the center bearing with lubricant, the center bearing is located in the center of the

spring bar/torsion tube where the spring(s) bolt to the center bracket.

Finally spray lubricant on the end bearing plates, the end bearing plates are on the outer ends

of the spring bar/torsion tube to the outside of the drums.

These steps can be done in any order, just be certain all parts receive lubrication.

Lubricating Garage Door Opener

First use a quality white garage door grease.

Next in a screw drive system. grease the entire length of the screw with the white garage door

grease.

in a chain drive system, grease the chain with a light coat of white garage door grease.

Nest in chain drive and belt drive system, apply a light coat of grease to the gear and sprocket,

be sure to replace he dust cover over the gear and sprocket.

Finally, in a chain drive and belt drive system lubricate the rail using either spray garage door

lubricant or a light coat of white garage door grease. this will allow the trolley to slide smoothly

along the rail. *Note: If using a spray lubricant, avoid spraying on or around the motor or

electronics as the lubricant can damage those parts.

Properly inspecting and lubricating your garage door system will increase the life and efficiency

of your entire garage door system.

Veteran Garage Door can perform this inspection and service for you as well as providing

repair and replacement options for any worn or damaged parts to keep your garage door

system performing at the highest level.

5/5 - (1 vote)