Garage door springs have long been made using oil tempered steel. Oil tempered garage door springs

are coated with oil when they are manufactured and have an oily film present when installed. This can

be troublesome if the installer does not take the time to wipe off oily hand prints from the garage door

panels and other painted surfaces after installation.

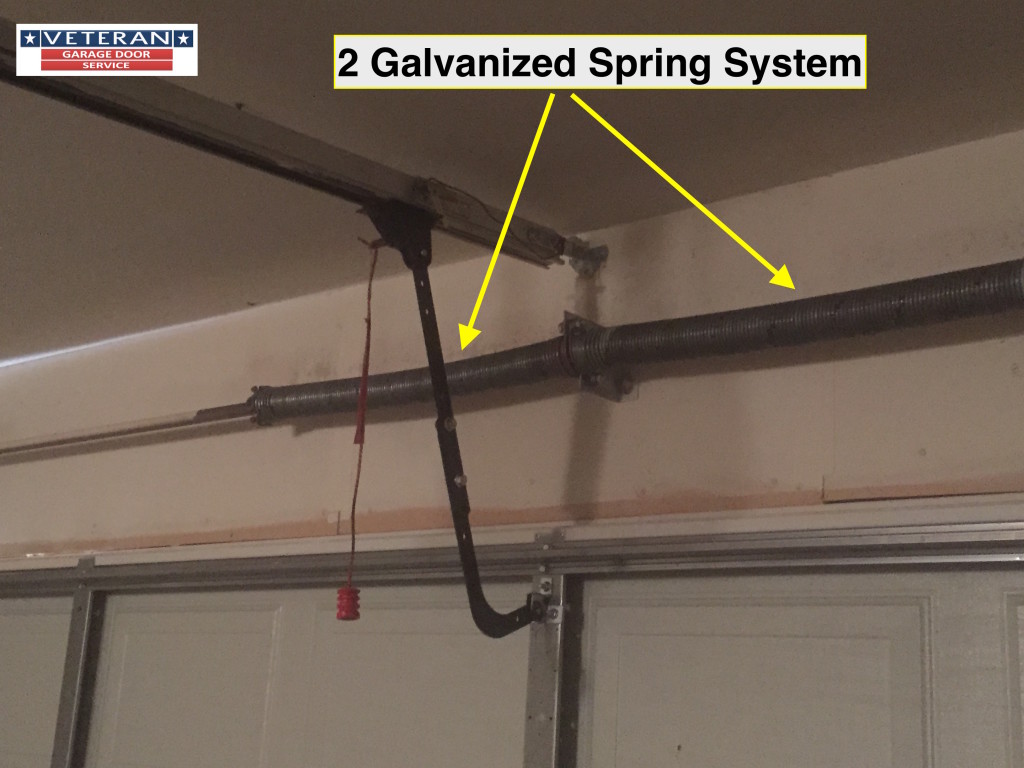

In the 1980’s manufacturers began the process of galvanizing garage door torsion springs. Galvanizing

garage door springs attempted to serve two purposes. the first was to attempt to improve the life of the

spring, and the second was to provide a cleaner spring.(without the oily coating) To galvanize the spring,

they started with the oil tempered steel spring and coated it with zinc. In most cases this was done by

dipping the steel spring into a hot bath of zinc allowing the zinc to coat the steel. It has been seen that

galvanizing the steel spring weakens the spring. Galvanized springs seem to need more adjustment over

the life of the spring than do the oil tempered steel springs. These adjustments require adding tension

to the springs which in turn shortens the life cycles of the springs.

Another alternative tried is coating oil tempered springs. This process involves using a paint like

substance to coat the spring and an electrical bonding to finish it. The problem here is in the finish, if

spots do not get bonded then moisture can penetrate the spring in those areas causing premature

breakage due to rust. Each of these processes is an attempt to prevent rust from developing on the

springs, rust will cause premature spring breakage in any spring.

The difference between galvanized and coated springs is the process of each. Galvanizing involves

dipping the steel spring into hot zinc and coating involves spraying the springs and using an electrical

bonding process. Each process is an attempt to seal the spring and prevent rusting from occurring. Each

process has its own different weakness.

In my opinion oil tempered springs are still the best thing on the market today. The process of

galvanizing steel springs weakens the steel and coating the steel springs leaves possible room for

moisture to penetrate the metal and cause rusting. The best answer to me is still to make it a practice of

oiling your spring with a quality garage door lubricant 2-3 times per year. Lubrication is the key to

prolonging the life of your garage door spring be it oil tempered, galvanized or coated. Oil will prevent

rust from forming and thus help to prolong the life of your garage door springs. The opinions here are

based on my experience with different springs and talking with other technicians.

As technology improves, there may be a better product, but as of now I do not see any benefit to either

the galvanized or coated springs over oil tempered springs. In fact I see distinct weaknesses to each

compared to oil tempered springs. Talk to your garage door technician about the differences and then

make the best choice for yourself.