To begin let’s start with understanding what the Wayne Dalton Torquemaster system is and what a

torsion spring system is. There are similarities, but there are also critical differences in each system.

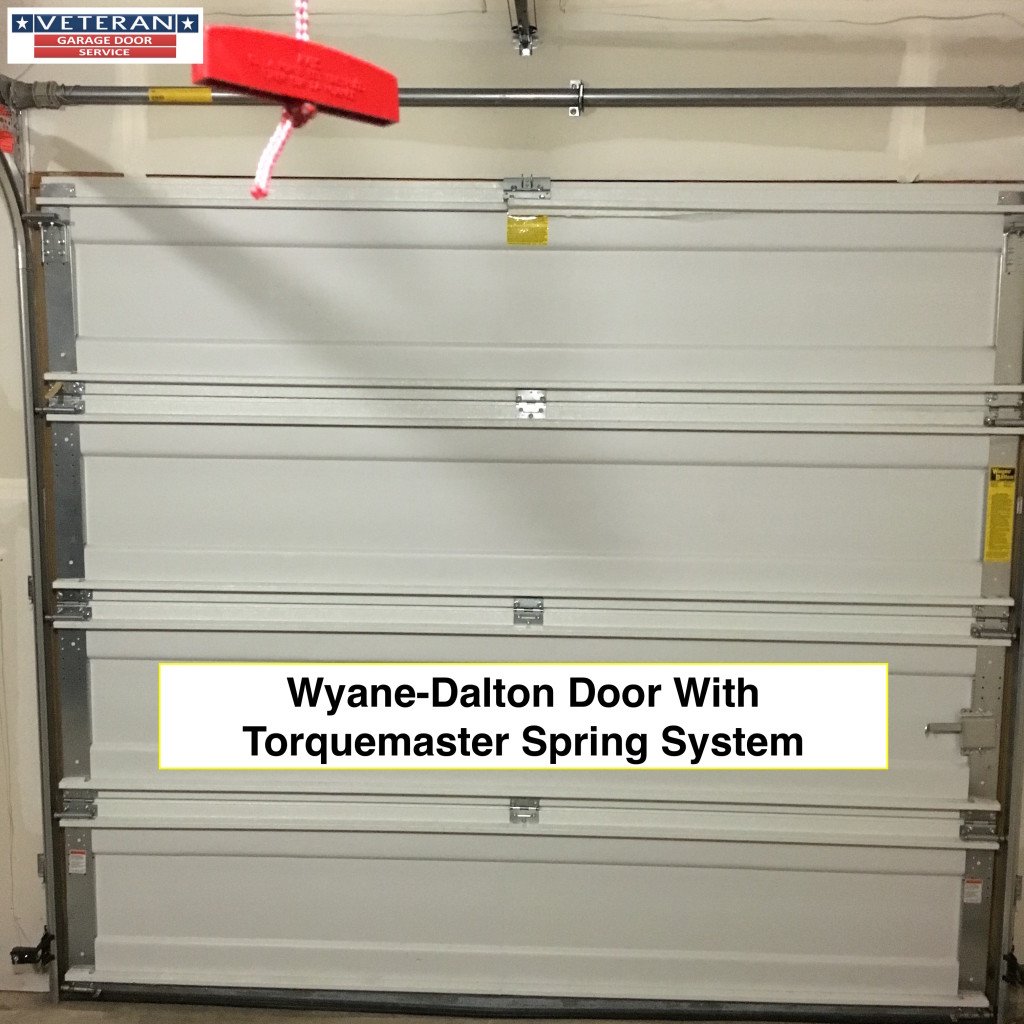

Wayne Dalton Torquemaster System:

Wayne Dalton designed the Torquemaster system in an attempt to improve on the torsion spring

system. He kept the idea of a spring bar/torsion tube mounted on the header above the garage door

opening on the inside of the garage. His system, however, utilizes one or two springs that are inside the

spring bar/torsion tube. The number of springs used is determined by the weight of the garage door.

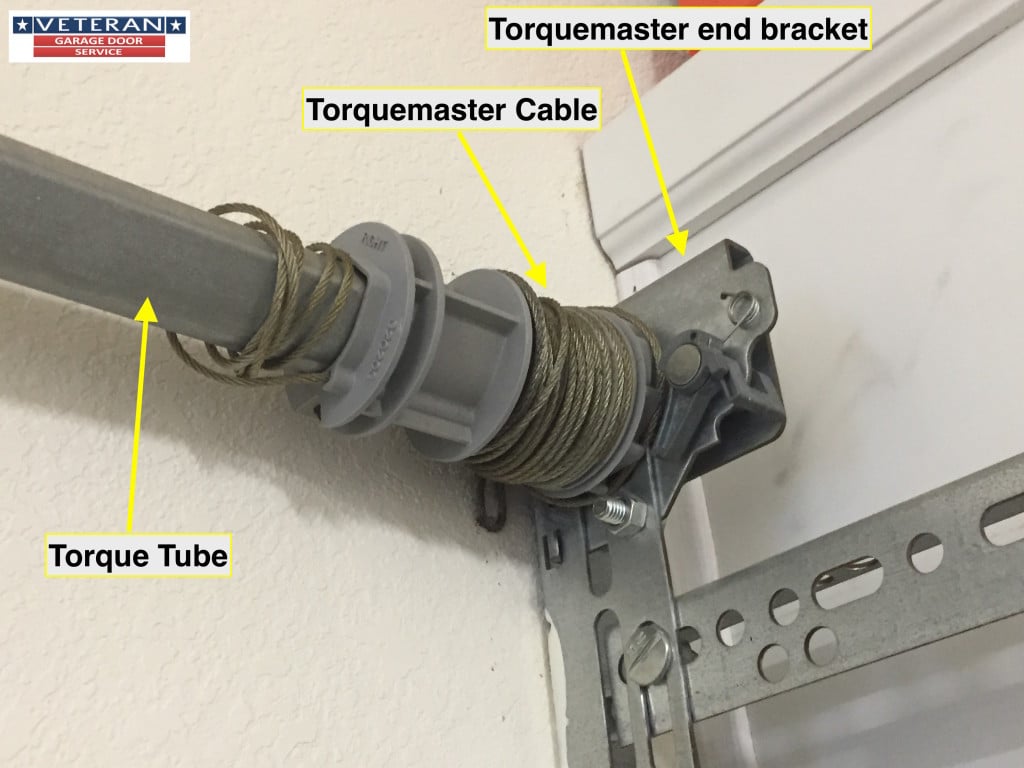

This system also utilizes small plastic drums mounted on each end of the spring bar/torsion tube. Cable

wrap around these plastic drums and then attach to the bottom bracket located on the bottom of the

bottom garage door panel on each side. In this system the internal springs provide the force to counter

balance the weight of the garage door while the cables and drums do the lifting. Winding these springs

to the proper tension involves using an electric drill, in older models, or a socket and socket wrench in

newer models. The spring(s) are then wound a set number of times depending on the weight of the

garage door. In the Wayne Dalton Torquemaster system if only one spring is used the spring winder will

always be on the right side and on a two spring system there will be a spring winder on each end. In a

Torquemaster two spring system you must always wind the right spring first and then the left, per

manufacturer instructions. The springs in a Wayne Dalton Torquemaster system are of a very small

diameter and wire size and thus require more winds to provide the strength to counter balance the

weight of the garage door. These extra winds add more stress to the springs causing them to fail sooner

than normal torsion springs. The concept was to protect the spring(s) from dirt, dust and rusting by

installing them inside the spring bar/torsion tube. In theory this seems like a good idea however in

application it has its limitations and problems.

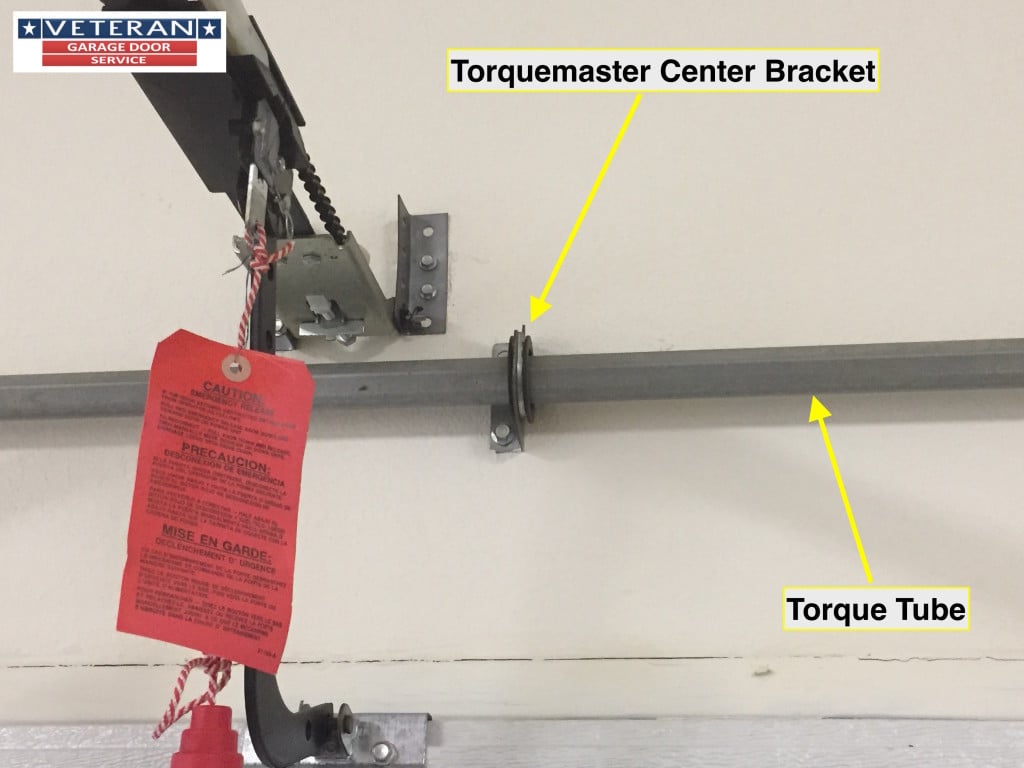

The biggest problem is the process of repairing a broken spring in the Wayne Dalton Torquemaster

system. As discussed earlier the extra winds to the spring(s) in the Torquemaster system leads to

premature failure. First it is hard to be sure if a spring in the Torquemaster system has failed, because

the spring(s) are inside the spring bar/ torsion tube. The best sign of spring failure in this system is an

unbalanced garage door. An unbalanced garage door will be heavy and difficult to open manually and

will fall to the floor at each break in the garage door sections/panels. A well balanced door will be easy

to open manually and will stop and stay at each break in the panels/sections. It will not fall to the floor

or try to fly open. Replacing a broken or failing spring(s) in the Torquemaster system is very labor

intensive. You first have to unwind any tension on the spring(s). Next you must remove the spring

winder(s) and gears inspecting each of these plastic parts for damage or wear, and replacing if needed.

Remember to always start on the right side. The only way to know if you have one or two springs is

there will be a winder on both ends in two spring system and only on the right in a one spring system.

next you must remove the spring bar/ torsion tube and place it on the ground. Finally you must pull the

spring(s) out of the spring bar/ torsion tube, a plastic spacer will also pull out with the spring(s). The

spacer is installed to keep the spring(s) from rattling inside the spring bar/torsion tube. Now you are

ready to install the new spring(s) and reinstall all the parts you just removed, do this in the reverse order

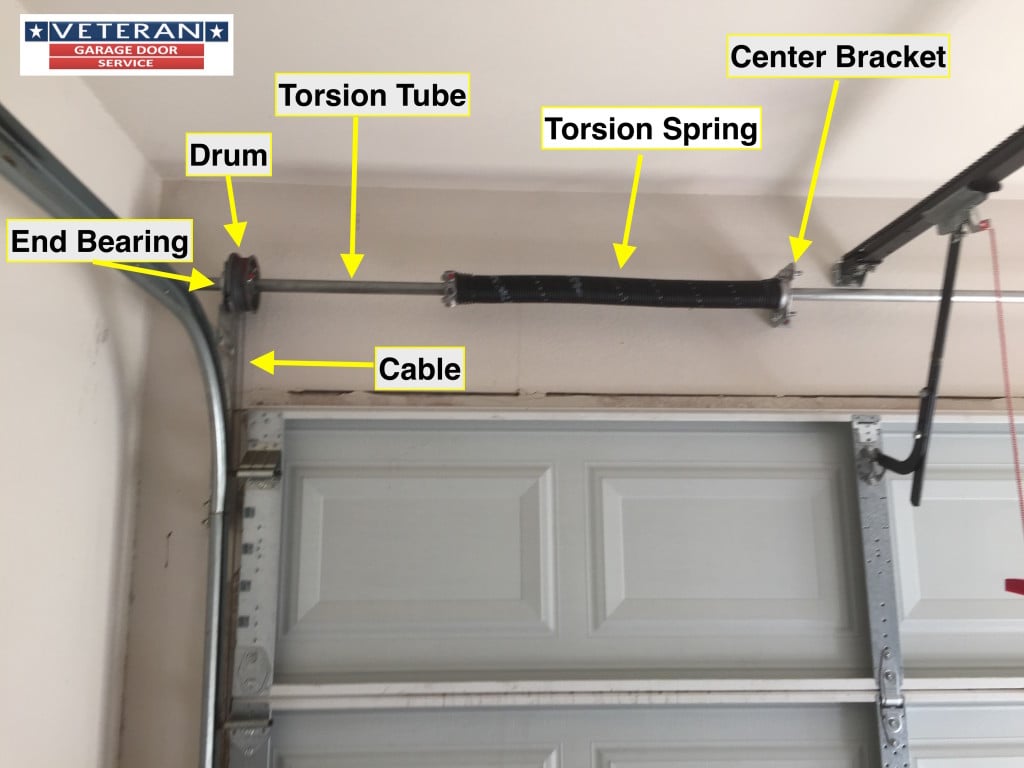

Torsion Spring system:

The torsion spring system utilizes a spring bar/torsion tube mounted on the header above the garage

door on the inside. Spring(s)are mounted on the spring bar torsion tube, on the outside of the bar and

are visible for inspection. metal drums are mounted at each end of the torsion tube. Cables attach to

the bottom bracket located on the bottom of the bottom section/ panel on each side of the garage

door. The cables then travel up the height of the garage door and attach to the drums. the cables wind

around the drums when the door is opened and unwind as the door is closed. In the torsion spring

system, the springs provide the force to counter balance the weight of the garage door, while the cables

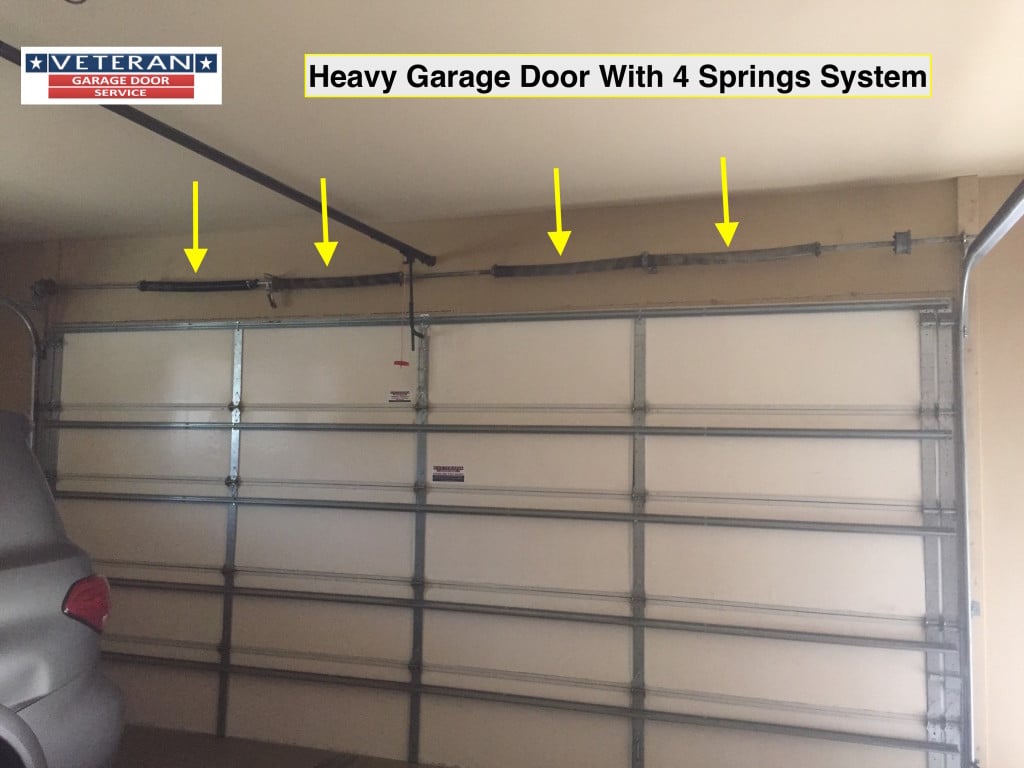

and drums do the lifting. In a torsion spring system, you can have one spring or multiple springs

depending on the weight of the garage door. Each spring is visible making it easy to identify a broken

spring. In the case of failing springs that have not yet broken you would still need to check the balance

of the garage door. While the springs are visible it is impossible to determine visually if the spring(s) are

failing unless one or more springs has actually broken. We recommend regular maintenance be

performed on garage doors that include lubricating the spring(s) with a quality garage door lubricant.

The torsion spring system does allow for this maintenance to be done.

When a spring breaks or fails, the process for replacing the broken spring(s) is less labor intensive,

although it does require the proper tools and training. This process requires unwinding any tension on

the torsion spring(s) using winding bars. Next you have to loosen the drum set bolts and remove the

cables from the drums. the next step is to loosen the set bolts on the cones of the spring(s) and unbolt

the spring(s) from the center bracket. The spring bar/ torsion tube may now be moved back and forth

allowing the drums to be removed from the spring bar/ torsion tube. Once the drum is removed you can

slide the old spring off and then slide the new spring into place and then slide the drum back on the

spring bar/ torsion tube. If you have two springs you will follow the same steps to remove and replace

the second spring on the other end of the spring bar/torsion tube. With the spring(s) and drums

reinstalled on the torsion tube you must begin the process of winding the cables around the drums and

winding the torsion spring(s) the proper number of times. We recommend having a trained garage door

technician perform any spring replacement or adjustment as garage door springs are dangerous and can

cause serious property damage or injury including death, if proper tools and techniques are not used.

Spring replacement is not a do-it-yourself project for the homeowner.

We always recommend converting Wayne Dalton Torquemaster systems to standard torsion spring

systems. We feel the torsion spring system is superior to the Torquemaster system and the cost to

convert the system is about the same as repairing the Torquemaster System. A conversion kit for an 8′-9′

wide door will cost about $285.00 plus labor, 15′-16′ wide door about $350.00 plus labor and 17′-

18’door will cost about $375.00 plus labor. These cost are averages and may be different where you live